Sheet piles are steel sheets with interlocking edges that retain soil and are installed using vibratory and vibration-free rigs.

Common uses

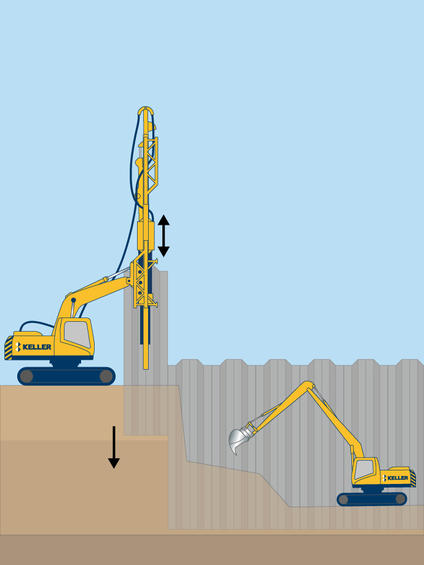

Process

Sheet piles are installed sequentially to design depth along the planned excavation perimeter or seawall alignment. The interlocked sheet piles form a wall for permanent or temporary lateral earth support with reduced groundwater inflow. Anchors can be included to provide additional lateral support if required.

Sheet pile walls have been used to support excavations for below-grade parking structures, basements, pump houses, and foundations, to construct cofferdams, and to construct seawalls and bulkheads. Permanent steel sheet piles are designed to provide a long service life. Vibratory hammers are typically used to install sheet piles. An impact hammer can complete the installation if the soils are too hard or dense. The sheets can be hydraulically pushed into the ground at sites where vibrations are of concern.

Cold-rolled sheet piling is less expensive but provides less water resistance. Hot-rolled sheet piling is more traditional and provides better water resistance.

Advantages

Quality assurance

Keller has a fleet of modern, safe rigs available to perform sheet pile installations in all environments. The in-house design allows us to customize a cost-effective solution for each project, and decades of experience allow us to avoid pitfalls in design and installation.